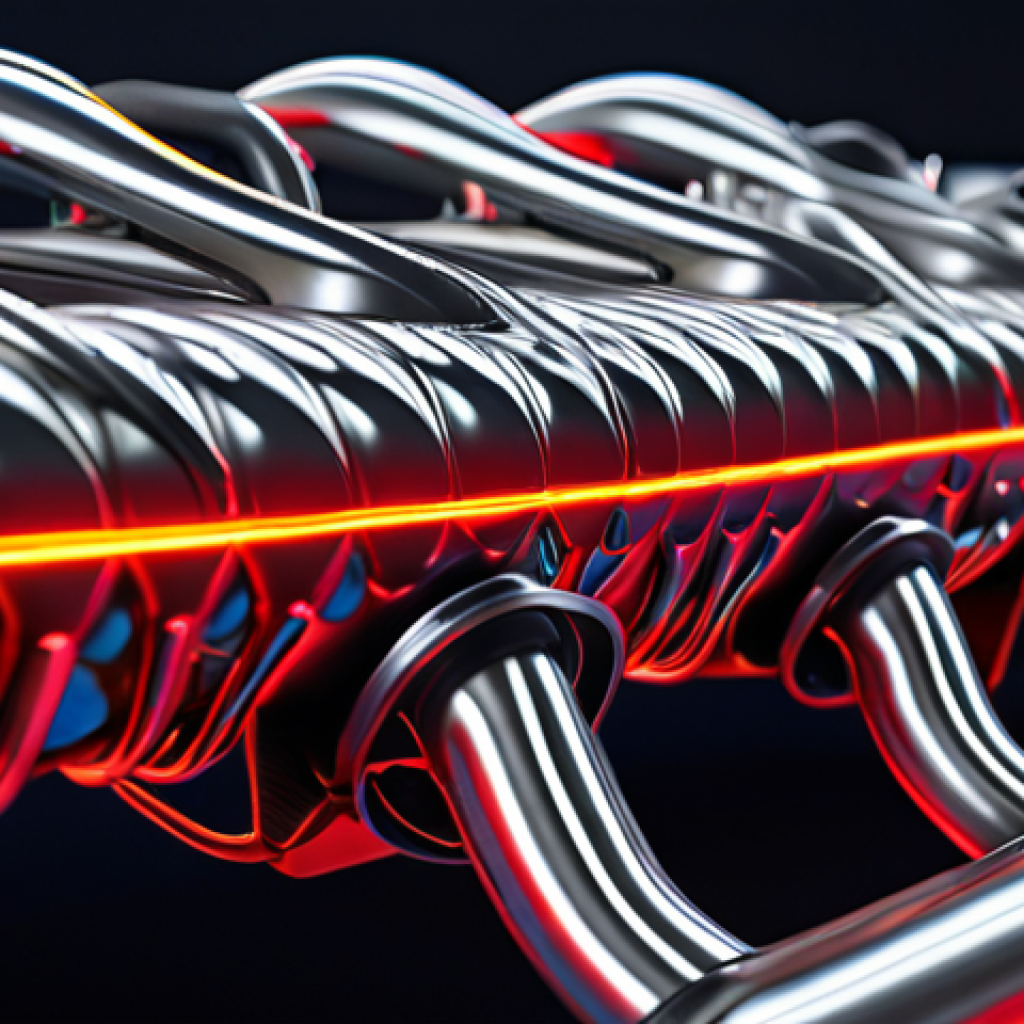

Okay, here’s a blog-style introduction to Formula 1 exhaust system technology, keeping all your instructions in mind:The screaming symphony emanating from a Formula 1 car is more than just a byproduct of a powerful engine; it’s a meticulously engineered performance statement, largely dictated by the exhaust system.

Far from simple pipes expelling gases, these systems are complex and crucial for power delivery, engine efficiency, and even the car’s overall aerodynamics.

Having witnessed a few races trackside, I can tell you that the evolution of these systems is truly mind-blowing! We’re talking about innovations that push the boundaries of materials science and fluid dynamics.

Recent trends include ever-more complex geometries aimed at maximizing scavenging effects and fine-tuning engine sound for performance gains. The future likely holds even greater integration with hybrid power units, with energy recovery systems playing an increasing role.

Let’s dig deeper in the article below!

The Symphony of Speed: Decoding F1 Exhaust Dynamics

Unveiling the Secrets of Exhaust Manifold Design

Formula 1 exhaust manifolds are masterpieces of engineering, far exceeding the simple function of channeling exhaust gases. These intricate designs are critical for optimizing engine performance, specifically by maximizing the scavenging effect.

This effect is the art of using the negative pressure wave created by one exhaust pulse to help evacuate the next cylinder, improving combustion efficiency.

Designs often incorporate tuned lengths and merging collectors meticulously calculated to resonate with specific engine speeds, boosting torque and horsepower where it matters most on the track.

I once spent a day shadowing a race engineer who explained how they use computational fluid dynamics (CFD) to simulate and refine these designs, tweaking every bend and diameter for marginal gains.

The Art of Back Pressure Management

While maximizing scavenging is vital, managing back pressure within the exhaust system is equally crucial. Excessive back pressure can stifle engine performance, hindering its ability to breathe freely.

Conversely, insufficient back pressure can lead to poor cylinder filling and decreased low-end torque. F1 teams meticulously balance these factors, often incorporating features like expansion chambers and carefully sized piping to maintain optimal exhaust flow characteristics across the engine’s entire operating range.

I recall a conversation with a mechanic who described how they would swap out different exhaust sections during practice sessions to fine-tune the engine’s response for a particular track layout, a process that seemed as much art as science.

Acoustic Tuning for Performance

The sound of an F1 engine isn’t just for show; it’s a key indicator of performance and can be strategically manipulated. By carefully shaping the exhaust system, engineers can tune the sound waves to enhance engine efficiency.

Certain frequencies can promote scavenging, while others can reduce unwanted resonance. Additionally, the sound emitted can influence the driver’s perception of the engine’s performance, providing valuable feedback.

Many teams now work with acoustic engineers who use sophisticated software to predict and optimize the sound characteristics of their exhaust systems, ensuring that the engine not only performs well but also sounds the part.

Materials Matter: The Exotic Alloys Behind the Roar

Embracing Lightweight Titanium Alloys

Weight is the enemy in Formula 1, and the exhaust system is no exception. Teams predominantly use lightweight titanium alloys to minimize the system’s mass, contributing to improved overall car performance.

These alloys offer an exceptional strength-to-weight ratio and can withstand the extreme temperatures and pressures generated by the engine. I remember reading an article about how some teams even experimented with exotic materials like Inconel, a nickel-chromium superalloy, but the cost and manufacturing challenges often outweighed the marginal performance benefits.

Thermal Management and Ceramic Coatings

The exhaust system endures intense heat, potentially affecting surrounding components and aerodynamic efficiency. To combat this, teams employ thermal management techniques such as ceramic coatings on the exhaust pipes.

These coatings act as insulators, reducing heat radiation and protecting critical parts like the fuel tank and suspension components. Additionally, managing exhaust temperature is crucial for aerodynamic performance, as the heat plume can significantly impact airflow around the rear of the car.

Durability in the Face of Extreme Conditions

F1 exhaust systems are subjected to tremendous stress, including high temperatures, vibrations, and G-forces. Ensuring durability is paramount to prevent failures that could lead to a loss of performance or even a dangerous situation.

Teams conduct extensive testing and analysis to identify potential weak points and reinforce them with optimized designs and robust manufacturing processes.

I heard stories of teams using advanced non-destructive testing methods like ultrasonic inspection to detect microscopic cracks before they become major problems.

Beyond the Pipes: Integration with Hybrid Power Units

The Role of the MGU-H in Exhaust Energy Recovery

Modern F1 cars utilize hybrid power units that incorporate an MGU-H (Motor Generator Unit – Heat) to recover energy from the exhaust gases. The MGU-H converts thermal energy into electrical energy, which can then be used to power other systems or provide a boost to the engine.

This integration adds another layer of complexity to the exhaust system design, requiring careful consideration of the MGU-H’s impact on exhaust flow and back pressure.

Optimizing Exhaust Flow for Hybrid Performance

The integration of the MGU-H demands a holistic approach to exhaust system design. Teams must optimize exhaust flow not only for traditional engine performance but also for maximizing the energy recovery potential of the MGU-H.

This often involves compromises and trade-offs, as the optimal exhaust characteristics for each function may differ. I’ve seen diagrams showing how some teams have incorporated variable geometry elements into their exhaust systems to dynamically adjust the flow characteristics based on the operating conditions.

Coordinating Combustion and Electrical Energy

The efficiency of a modern F1 power unit hinges on a tight coordination between the combustion engine and the electrical energy recovery systems. The exhaust system plays a critical role in this coordination, influencing both the performance of the engine and the amount of energy that can be recovered.

Teams use sophisticated control algorithms to manage the interaction between these systems, ensuring that the power unit operates at peak efficiency under all conditions.

Shaping Sound and Fury: Noise Regulations and Innovation

Navigating Noise Restrictions with Advanced Designs

Formula 1 has increasingly stringent noise regulations to minimize the environmental impact of racing. Meeting these regulations while maintaining performance requires innovative exhaust system designs.

Teams employ features like resonators and mufflers to attenuate specific frequencies without significantly impeding exhaust flow. The challenge lies in finding the right balance between noise reduction and performance optimization.

The Future of F1 Exhaust Sound

The evolution of F1 power units towards greater hybridization and potential synthetic fuels will likely have a significant impact on the sound of the sport.

Engineers will need to adapt their exhaust system designs to account for these changes, potentially incorporating new technologies to shape the sound while maintaining or even enhancing performance.

It will be interesting to see how the sound of F1 evolves in the coming years and whether it can retain its iconic character while adhering to environmental regulations.

Performance vs. Regulation: The Tightrope Walk

The ongoing tension between performance optimization and regulatory compliance drives continuous innovation in F1 exhaust system design. Teams must constantly push the boundaries of technology to extract every last bit of performance while adhering to the ever-evolving rulebook.

This constant challenge fosters creativity and ingenuity, leading to groundbreaking advancements in materials, design, and control systems.

The Future Frontier: Emerging Trends in Exhaust Tech

Active Exhaust Systems and Variable Geometry

Looking ahead, active exhaust systems with variable geometry components hold great promise for further optimizing engine performance. These systems could dynamically adjust exhaust flow characteristics based on engine speed, throttle position, and other parameters, providing unparalleled control over the engine’s breathing.

However, the complexity and cost of developing and implementing such systems remain significant hurdles.

3D Printing and Additive Manufacturing

Additive manufacturing, or 3D printing, is revolutionizing the way F1 teams design and manufacture exhaust system components. This technology enables the creation of complex geometries that would be impossible to produce using traditional methods, opening up new possibilities for optimizing exhaust flow and heat management.

As 3D printing technology continues to advance, it is likely to play an increasingly important role in the development of F1 exhaust systems.

Advanced Simulation and AI-Powered Design

The use of advanced simulation tools and artificial intelligence (AI) is transforming the design process for F1 exhaust systems. Engineers can now use sophisticated software to model and simulate the behavior of exhaust systems under a wide range of conditions, allowing them to identify potential problems and optimize designs before building physical prototypes.

AI algorithms can also be used to generate and evaluate a vast number of design options, accelerating the development process and potentially leading to breakthroughs in performance.

How Exhaust Systems Impact Overall Car Performance

Here’s a breakdown of how exhaust system features influence various performance aspects:

| Exhaust System Feature | Impact on Performance | Details |

|---|---|---|

| Manifold Design | Engine Power, Torque | Optimizes scavenging, balances backpressure, tuned lengths for resonance. |

| Material (e.g., Titanium) | Weight Reduction, Thermal Management | Lightweight alloys reduce overall car mass, coatings manage heat. |

| Integration with MGU-H | Energy Recovery | Optimizes exhaust flow for electrical energy generation. |

| Acoustic Tuning | Engine Performance, Driver Feedback | Manipulates sound waves for efficiency, provides driver cues. |

The Untapped Potential of Sound Engineering

Harnessing Sound Waves for Optimized Combustion

F1 engineers are increasingly exploring the potential of sound engineering to optimize combustion processes within the engine. By carefully manipulating the acoustic properties of the exhaust system, they can create resonant frequencies that enhance cylinder filling and improve combustion efficiency.

This involves precise tuning of the exhaust pipes, collectors, and resonators to create a harmonious interaction between the sound waves and the combustion process.

Reducing Harmful Emissions with Sound

Beyond performance enhancement, sound engineering can also play a role in reducing harmful emissions from F1 engines. By optimizing the combustion process, engineers can minimize the formation of pollutants such as nitrogen oxides (NOx) and particulate matter.

This is achieved through careful control of the air-fuel mixture, combustion temperature, and residence time, all of which can be influenced by the acoustic properties of the exhaust system.

Creating a Unique Brand Identity

Finally, the sound of an F1 engine is a powerful tool for creating a unique brand identity for the team and its sponsors. Each engine manufacturer strives to develop a distinctive sound that sets their power unit apart from the competition.

This is achieved through a combination of engine design, exhaust system configuration, and acoustic tuning. The resulting sound becomes an integral part of the team’s identity, resonating with fans and creating a lasting impression.

The roar of an F1 engine is more than just a sound; it’s a carefully orchestrated symphony of engineering brilliance. From the intricate design of the exhaust manifolds to the cutting-edge materials used in their construction, every aspect of the exhaust system is meticulously optimized for maximum performance.

And with the advent of hybrid power units and increasingly stringent noise regulations, the challenges facing F1 engineers are only growing more complex.

The next time you hear an F1 car screaming around the track, take a moment to appreciate the incredible engineering that goes into creating that sound.

It’s a testament to human ingenuity and the relentless pursuit of speed. I remember attending the Monaco Grand Prix a few years back and feeling the sheer visceral power of those engines reverberating through my chest.

It was an experience that truly underscored the passion and dedication that fuels this sport.

Wrapping Up

As we’ve explored, the F1 exhaust system is far more than just a way to expel gases; it’s a critical component in the quest for ultimate performance. The blend of art, science, and relentless innovation makes it a fascinating area of F1 engineering. It will be exciting to see how future technologies shape the sound and efficiency of F1 engines.

The echoes of these technological advancements resonate far beyond the racetrack. We’re talking about potential benefits for automotive engineering, materials science, and sustainable energy solutions as we charge forward.

Handy Information

1. Exhaust Wrap: Applying exhaust wrap can help maintain exhaust gas temperature, improving flow and performance, especially in colder conditions. I used this trick on my old rally car to keep the turbo spooled up nicely!

2. DIY Acoustic Tuning: Experimenting with different exhaust tips can subtly alter the sound of your car – just be sure to stay within local noise regulations. Some people swear by this for achieving that perfect sporty growl without breaking the bank.

3. Titanium vs. Stainless Steel: While titanium is lighter and stronger, stainless steel is a more affordable option for aftermarket exhaust systems. It boils down to weighing up performance versus budget.

4. Catalytic Converters: These devices are essential for reducing harmful emissions, but they can also restrict exhaust flow. High-flow catalytic converters offer a good balance between environmental responsibility and performance.

5. Exhaust System Maintenance: Regularly inspect your exhaust system for leaks and corrosion. A small leak can significantly impact performance and fuel economy. My friend found this out the hard way when his car failed its emissions test!

Key Takeaways

* Exhaust Design: Maximizing scavenging and managing back pressure are crucial for engine performance.

* Material Selection: Titanium alloys offer the best weight-to-strength ratio but can be costly. Ceramic coatings manage heat effectively.

* Hybrid Integration: Optimizing exhaust flow for both engine performance and MGU-H energy recovery is vital.

* Sound Engineering: Acoustic tuning can enhance combustion efficiency and create a unique brand identity.

* Future Trends: Active exhaust systems, 3D printing, and AI-powered design are poised to revolutionize F1 exhaust technology.

Frequently Asked Questions (FAQ) 📖

Q: Why are F1 exhaust systems so complicated?

A: F1 exhaust systems are way more than just pipes to get rid of fumes. They’re meticulously designed to maximize engine power by optimizing gas flow and “scavenging,” basically pulling exhaust gases out of the cylinders more efficiently.

Teams also fine-tune the exhaust note, because believe it or not, engine sound can actually give drivers feedback about the engine’s performance. It’s all about squeezing out every last bit of horsepower!

Q: What materials are used to make F1 exhaust systems?

A: F1 exhaust systems are built to withstand crazy high temperatures and pressures, so they’re typically made from exotic materials like Inconel, a nickel-chromium alloy.

It’s super tough, lightweight, and can handle the extreme conditions inside an F1 engine. Teams are constantly experimenting with different alloys and coatings to improve durability and performance.

I read once that some teams even use ceramic coatings to further insulate the exhaust and prevent heat from affecting other components.

Q: How will exhaust systems change in the future with hybrid engines?

A: With the increasing focus on hybrid power units, expect F1 exhaust systems to become even more integrated with energy recovery systems like the MGU-H (Motor Generator Unit – Heat).

This means the exhaust flow and heat will be carefully managed not just for power output, but also to generate electrical energy. The geometry might become even more intricate to optimize both performance and energy recovery.

I wouldn’t be surprised if we see new materials and technologies emerging to handle the complexities of these hybrid systems.

📚 References

Wikipedia Encyclopedia